Over fifty years ago, Kenneth H. Striebel founded his first small shop in Kokomo, Indiana to make parts for the furniture industry. Ever since that time, furniture has been a way of life for the Striebel family. Dimensions’ growth over the years has been due to our ability to gather together a valued group of employees who share our passion for furniture. Collectively, the Dimensions' management team has nearly a century and a half of combined experience in all facets of the furniture industry.

While we value and honor the past, we also look toward the future. For example, Dimensions hires its designers from some of the nation's top furniture design programs, such as Indiana University's Herron School of Furniture Design, and the Rhode Island School of Design. These bright young minds represent the next generation of our industry. It is they that provide the fresh perspectives that keep our company at the cutting edge of furniture design and technology.

Back to top

To meet the demands of today's customers for quality products at an affordable price requires a company that is able to access the best from throughout the world. Whether it's premium top grain leathers from tanneries in Italy, finely woven fabrics from North Carolina, or the world's best quality walnut veneers right from our home state of Indiana, Dimensions has the ability to bring together the best materials and designs from throughout the world. Dimensions relies on the on-site presence of its staff from around the world to make sure that every part of the supply chain is doing its part to ensure we meet our customers' requirements.

Dimensions' overseas operations are based in southern China. Our Asia team has approximately 150 years of combined experience in the furniture industry. The product development managers on our Asia staff each have an average of over ten years of furniture experience. Their technical expertise gives them the ability to translate our USA team's designs quickly into a format the factories can use as the basis for beginning the manufacturing process. Their practical hands-on experience of making furniture in Asian factories provides them the knowledge necessary to allow them to spot and correct potential problems before production of an item begins.

Through our staff of quality control supervisors located in Dimensions' offices in central and southern China, every factory we work with has at least one Dimensions quality control person on site for the entirety of the production run at that factory. Quality problems do not just occur at the end of production, so our QC team watches production of all products from the first cutting of wood, through the finish, assembly, and/or upholstery processes. Sub-makers are often the greatest cause of quality problems on furniture made in Asia, so our QC team also inspects all parts provided by sub-makers either at the sub-maker or as soon as they are received at the factory. The Dimensions QC staff for each factory is responsible for issuing a signed inspection report that photographs and documents all the important specifications on the order. Every item we produce is marked and identified by our QC staff, so we can trace any problems back to both the factory and the QC staff responsible and hold them accountable.

Back to top

Dimensions got its start as a business producing large orders for some of the nation's biggest retailers, such as Costco, Sam's Club, and Target. As buying habits have changed over the years, catalog and internet retailers have grown to become an increasingly important source of sales in the industry in general and for Dimensions in particular. Dimensions has developed a set of capabilities that make us uniquely qualified to meet the needs of internet retailers for a large number of different items in limited quantities.

When a large retailer orders many containers of one product in one color combination there are certainly many suppliers able and willing to produce such an order. However, providing the smaller quantities that internet and catalog customers demand creates its own set of special challenges. Dimensions sells over 500 different s.k.u.'s in virtually every major category of residential furniture and contract seating. In terms of materials we make products using solid woods, veneers, fabric, leather, and both sheet and tubular steel. When one then throws in the added challenge of making many of these designs in both small quantities and on an exclusive basis as many of our customers require, it creates a set operational hurdles that very few companies are able to overcome.

Through developing long-term relationships with trusted suppliers and then overseeing those relationships with the assistance of our dedicated staff, we have developed a set of best practices that allow us to produce orders in very low quantities. As just one example, Dimensions often makes production runs of upholstered chairs in exclusive fabrics in quantities as low as 25 units.

Back to top

To truly understand what an organization stands for you should focus on the actions the organization takes. For Dimensions, sustainability is not a narrowly focused concept, but is instead a holistic concept that permeates all parts of our business. In everything we do, we operate under the principle that nothing is sustainable unless you give back more than what you take.

For a business to be sustainable for the long-term one must be willing to invest the company's resources back into the employees that are the lifeblood of the business. As a reflection of this belief, every Dimensions employee throughout the world shares in the profits of the company as a major source of their compensation. Dimensions realizes that we have two purposes for our existence. One is to provide a superior value to our customers. The other is to provide a good livelihood for our employees. The egalitarian culture of Dimensions is one in which every employee has a stake in making sure we satisfy the needs of our customer as the best means to provide for themselves and their family.

For a business to be sustainable, the communities in which the business operates must be healthy. As part of our commitment to our community, Dimensions donates hundreds of pieces of furniture every year to the Hamilton County, Indiana chapter of Habitat for Humanity in an effort to help do our part to contribute to those looking to build a better future for themselves and our community.

For a furniture business to be sustainable we must make sure that the forests we depend upon to provide the materials for our furniture will be there for the next generation. For this reason, Dimensions Furniture donates a portion of its annual profits to the American Chestnut Foundation, which is a nonprofit organization dedicated to breeding a blight-resistant American chestnut tree and the reintroduction of this majestic tree to the forests of the eastern United States. In addition, through its reforestation efforts in the Striebel family timberlands in Indiana, we take an active, direct and ongoing role to make sure that the trees will be there to sustain the next generation of our business.

Back to top

The marketplace is constantly changing and the competition is quick to try to copy any successful new ideas. We realize that developing a great idea for a customer is only one-half of the equation. To maximize the benefit to customers requires that new ideas be brought to the market quickly. To make sure that we provide the highest level of service to our customers, Dimensions has developed the operational abilities to offer the following commitment to our customers:

After the idea for a project is provided by a customer, Dimensions will provide an initial rendering of the design in 10 days or less. Dimensions will provide a firm quote on a design within 7 days of the reciept of a customer's approval of that design. After a customer requests a sample, it can typically be produced and ready to ship in as little time as two weeks.

Within 60 days of approval of sample or design Dimensions will be able to deliver to port the first order of a new item. The lead time on any follow up orders would be 45 days on wood items and 50 days on items with a fabric designed for the customer.

Back to topThe best way to illustrate the true meaning of Dimensions' motto – Innovation for Living – is through some real world examples of how we have worked to find new ways to solve the challenges that our customers face.

Challenge – How to provide an affordable and environmentally friendly alternative to standard live edge table designs?

Challenge – How to provide an affordable and environmentally friendly alternative to standard live edge table designs?

Live edge tables have become an increasingly popular item with consumers who are seeking to bring the natural warmth and beauty of trees into their homes to create furniture that has a unique and organic appearance. The problem is that such trees require the use of large sections of older growth trees. This results in tables that often cost thousands of dollars and which make inefficient use of the scarce old growth hardwood timber.

Dimensions Answer: Dimensions developed a design that solves both of the problems with live edge tables. Our patent pending design blends together detailed castings taken from old growth trees, along with the high quality wood veneers and engineered wood materials to create a design that provides all the beauty that one would expect in a live edge table for 80% less than the cost of live edge tables made in the traditional manner. In addition, because our design is made primarily from engineered wood materials and wood veneers, it does not require the use of rare and precious old growth trees.

Challenge — How to provide space saving student seating that meets the needs of students while they are hard at work or play?

Challenge — How to provide space saving student seating that meets the needs of students while they are hard at work or play?

College students need seating that provides a comfortable and ergonomically correct chair for them to work at as well as a chair that is suited for them to use to relax. However, the small size of most college dorms and apartments puts space at a premium.

Dimensions Answer: Dimensions created a video rocker office chair that serves as a fully functional and ergonomic task chair. When a student is not studying, the seat section can be detached to create a comfortable video rocker while the base can be used as a mobile laptop stand.

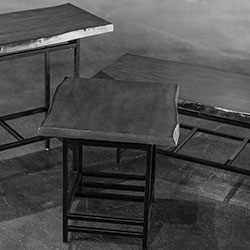

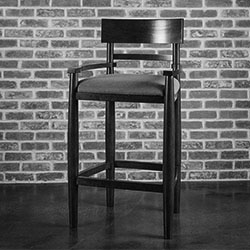

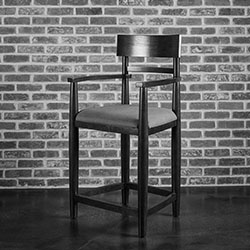

Challenge — How to help retailers minimize their inventory levels on the stools they sell?

Challenge — How to help retailers minimize their inventory levels on the stools they sell?

Some customers are only interested in purchasing bar height stools. However, many other customers need shorter counter height stools for use at their kitchen counters. This creates a problem for retailers because they are forced to hold inventory of two sizes of stools.

Dimensions Answer: Dimensions created an elegantly simple design that allows the customer to assemble either a a bar height stool or a counter height stool from a single item.

Back to top